The On-Line Activation System Triple Injection

- Delivers final-use solutions at desired ppm levels

- Easily adjustable concentrations (from 50 to 1200ppm)

- Maintains constant concentration in variable flow

- Easy Installation (only requires one water connection and 20″ x 30″ wall space)

- Water-driven proportional pump system (no electric wiring required)

- On-demand dispensing (no chemical waste)

- Easy to operate

- Accurate and reliable delivery of product

- Unaffected by changes in water pressure

- Low maintenance

Effective, reliable activation. The Bio-Cide Solution to sanitation and pathogen control.

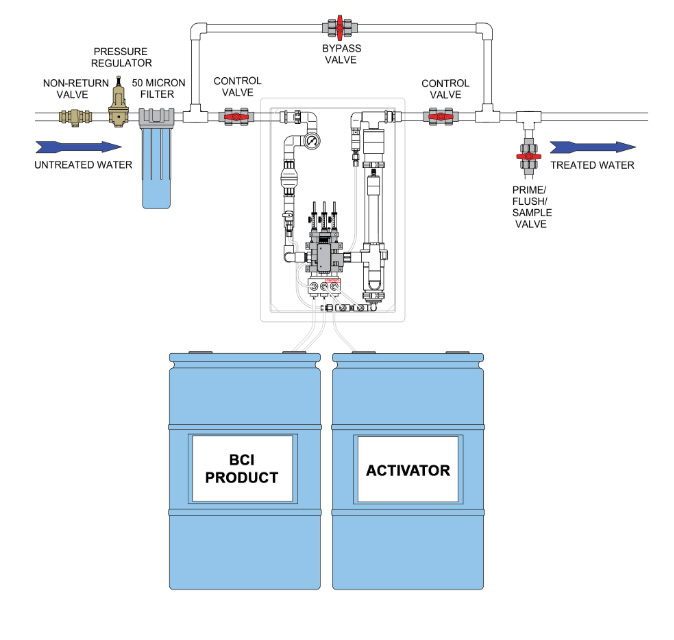

The OLAS Ti generates an adjustable concentration of acidified sodium chlorite, and injects it directly into a variable water stream. Installed in the water supply line, the system operates by using the flow of water as its power source. The concentration level can be easily adjusted and remains proportional to the volume of the water entering the system, regardless of variations in flow or pressure, which may occur in the water supply line. The OLAS Ti, through specifically designed programs with Keeper Professional, a Bio-Cide International, Inc, product, provides protection against pathogens like Salmonella, E. coli, Listeria and others in red meat, and poultry processing applications. Versatile and flexible, the compatibility of the OLAS Ti allows complete integration of a program to meet our customer needs with absolute assurance and reliability.

Specifications and Requirements

Water Pressure: 25 to 75 psi.

Water Temperature: 40°F to 100°F

Standard Unit Water Connection: The unit is equipped with 3/4″ female NPT connections to facilitate quick connection to any potable water source with the proper pressure rating.

Connection Output: 0.08 to 3 gallons per minute.

Concentration levels: The OLAS Ti can be adjusted to deliver concentration levels between 50 ppm – 1200 ppm

Note: The OLAS Ti can be factory modified if the specifications and requirements above do not meet the needs of a specific application. Specifications and requirements may differ according to modifications made.